RSSS Series – Stainless Steel Submersible Dewatering Pumps for Corrosive Drainage and Compact Installations

JS RSSS submersible pumps are engineered for efficient dewatering in corrosive environments, offering reliable performance in confined pits, casings, or basins. Designed with a slim profile and built entirely from corrosion-resistant SUS 316 stainless steel, these pumps are ideal for chemical processing, wastewater, marine, and aggressive fluid transfer.

-

Slimline top-discharge design enables easy installation in narrow pits and ensures optimal motor cooling during continuous operation.

-

All exposed wet parts are made of SUS 316 stainless steel for superior corrosion resistance and long service life.

-

Double mechanical seals protect internal components from liquid ingress and mechanical wear.

-

Viton® O-rings and elastomers provide exceptional chemical resistance.

-

Class F motor insulation handles elevated temperatures and heavy-duty cycles.

-

Shaft sleeve minimizes shaft wear caused by abrasive and corrosive media.

-

Lip seal protection prevents contaminants from reaching critical components.

-

Thermal overload protection prevents motor damage from overheating or excessive amperage.

-

Enhanced cable entry sealing system increases long-term reliability under harsh conditions.

RSSS

Model table Dewatering Pumps /RS

Available in 0.75–1.5 kW (1–2 HP) models, head up to 23 m, capacity up to 345 L/min, solids handling up to 6 mm

The models are equipped with a single-phase power supply with a voltage of 100-240 V and a three-phase power supply with a voltage of 200-600 V.

Come with a standard 10-meter cable.

Easily compare the hydraulic performance of all RSSS submersible pump models using the performance chart. It highlights how head (m) and flow rate (m³/h) vary across models—making selection easier for drainage, wastewater, and light chemical transfer applications.

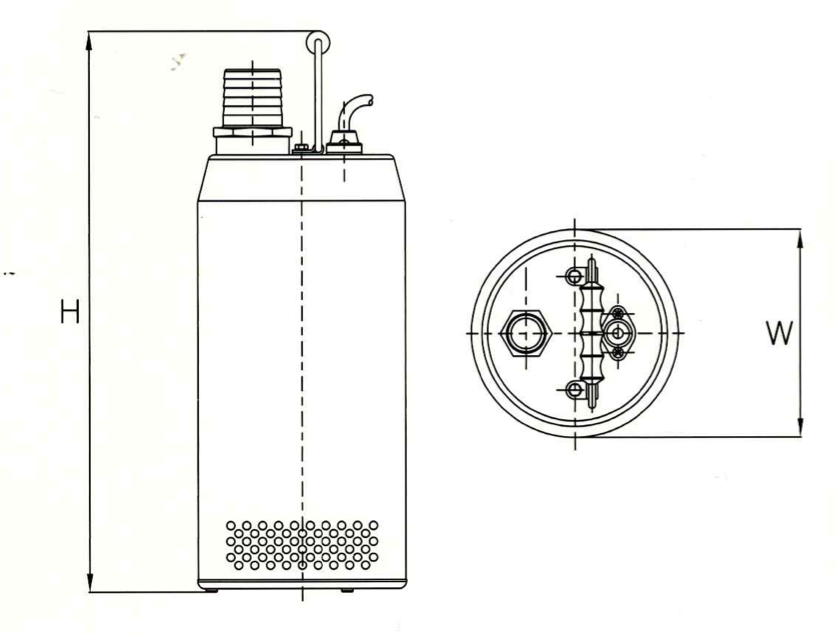

Dimensions(mm)

Watch KZN pumps in action — real-world performance footage

Construction Material:

-

Double mechanical seals provide effective leak protection over time

-

Class F insulation supports high-temperature performance

-

Shaft sleeve reduces shaft wear from abrasive and corrosive media

-

Lip seal acts as an extra barrier against contaminants

-

Thermal overload switch protects from overheating and electrical surges

-

Advanced cable entry sealing prevents moisture ingress and extends pump life